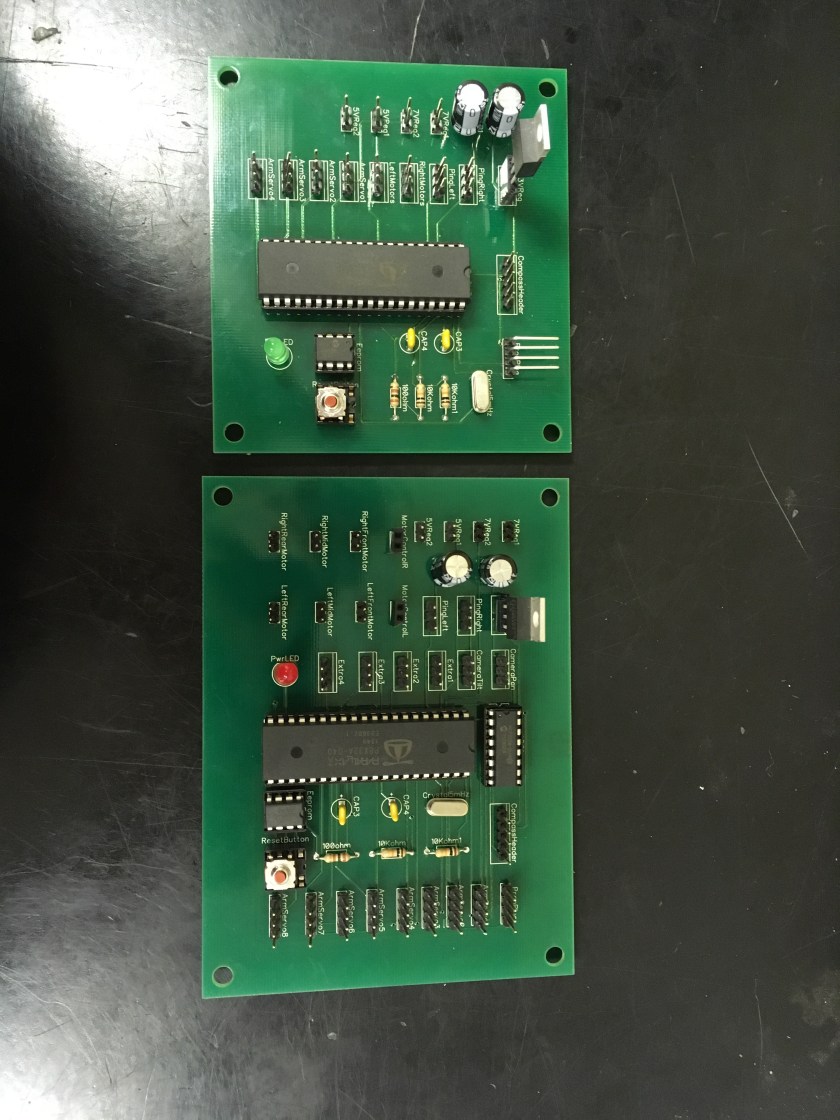

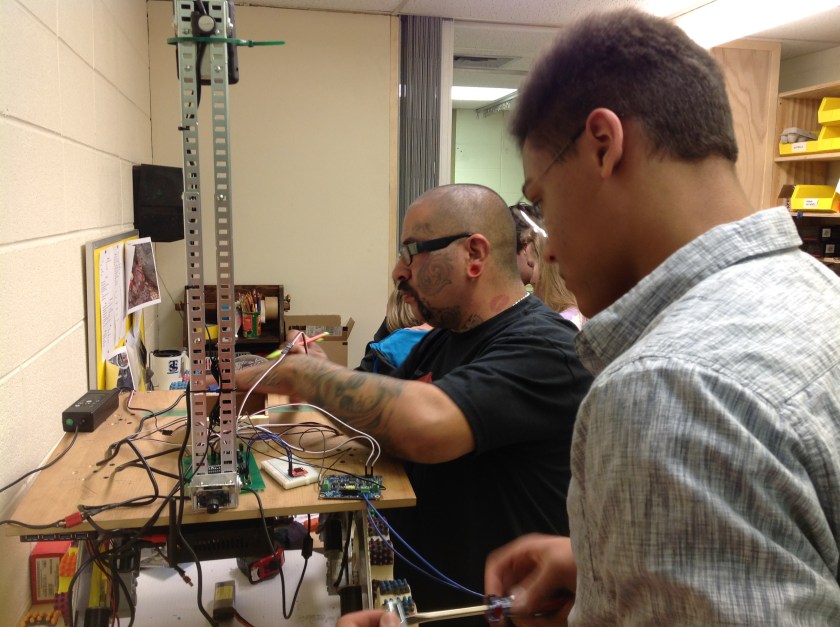

Today, we’ve figured out the dynamixal servos. The Programing team has figured out how to run the dynamixal servos in the propeller C language. The team was using an ardunio chip instead of the propeller chip. The reason the ardunio board was working and the propeller chip was not is because the circuit that “talks” to the dynamixles is designed to run on and arduino board, which operates on five volts. The propeller board runs on 3.3 volts. The way the programming team made it work was by using a propeller c breadboard to add in some transistors to increase the voltage output to 5 volts. With the modification the arm was able to run on the propeller chip.

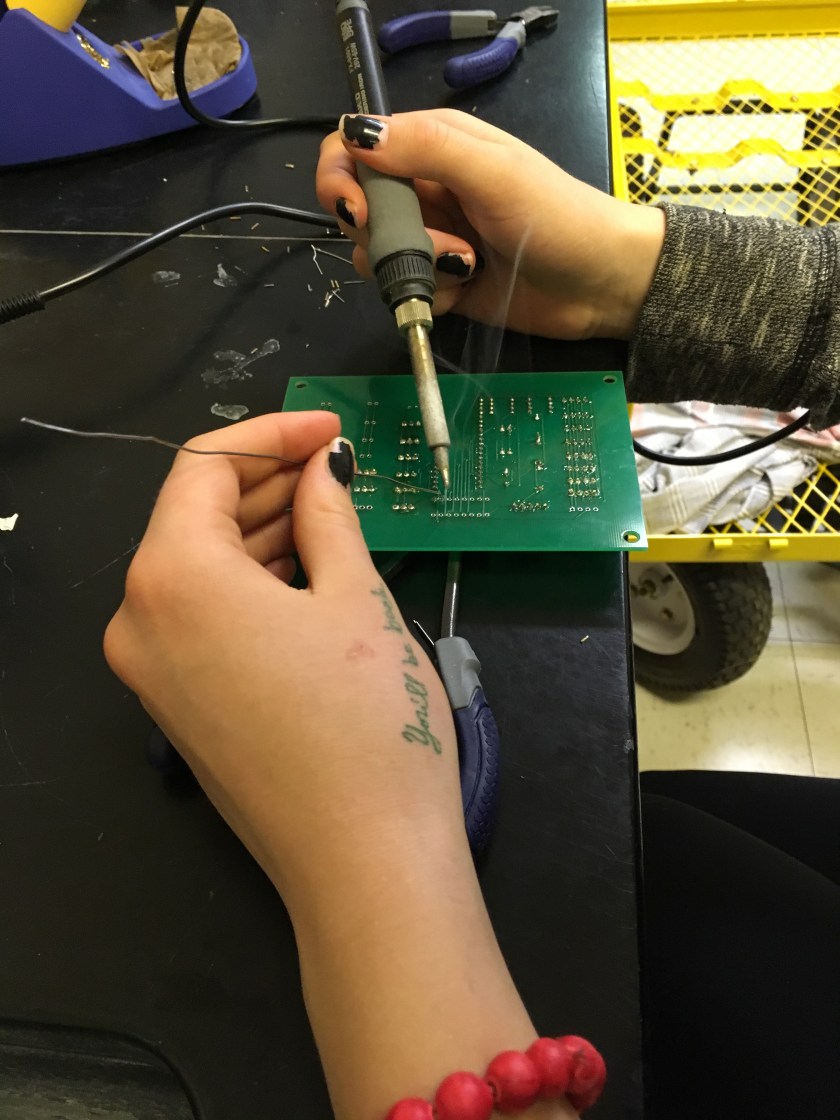

The electronics team soldered switches with fuses together. The two switches will act as a manual overrides to completely shut down the robot if anything goes wrong. The fuse will act as a buffer between a unnaturally large electric current and the the robot’s electronics.

The black half-cylinders in the bread board are the transistors.

We tested Caleb’s Hand design today (Plan C) and not only is it 55 g lighter, it successfully picked up the bigger rock. The second video shows that it may need some teeth however for the smoother rocks

Another hand design has been added to our list! Our 3rd or 4th hand design (who’s counting? ) was designed by our very own Caleb Williamson. Seychelle used her resources in finding ways to dry this ring-pop colored plasi-dipped hand.

Another hand design has been added to our list! Our 3rd or 4th hand design (who’s counting? ) was designed by our very own Caleb Williamson. Seychelle used her resources in finding ways to dry this ring-pop colored plasi-dipped hand.